algorithmica’s machine learning enables predictive maintenance and optimization

Aging plants have a wealth of process data stored in their archives. Machine learning can turn this data graveyard, usually used for little more than drawing diagrams, into a dynamic mathematical model of the plant’s behavior. This model is used to compute when in the future equipment will break and how to change the setpoints in order to improve plant performance. algorithmica was founded thirteen years ago by mathematician Dr. Patrick Bangert, who felt a strong desire to bridge the gap between the world of academic mathematics and the world of industry. Their motto “simply intelligent” reflects the desire to protect their customers from the complexities of mathematics and rather to deliver simple answers to highly complex questions using intelligent methods.

This is the cover story of April 2018 in Managing Aging Plants.

The immense potential of mathematics, in particular machine learning, was what drove Dr. Bangert to leave his position as a Professor of Mathematics at the Jacobs University in Bremen (Germany) and start thinking about how he could actually apply the applied mathematics outside the university context. “It is difficult to get it out of the ivory tower and into industry practice,” he tells. The benefits of implementing machine learning into plants in the chemical, power generation, and oil & gas industry are huge. “The first thing that really came to light was the use case of predictive maintenance. What this basically means is that with machine learning you will be told exactly when an asset will fail.”

K+S considers itself as a customer focused, independent minerals company for the segments of Agriculture, Industry, Consumers, and Communities. It operates numerous facilities to produce potash and salt products. Potash ore cannot be used in its raw form but must be refined. As a last step of the refining process the potassium chloride is washed to reach the desired quality of the end product. Afterwards it is dried and stored for shipment. It is this washing process that algorithmica’s software optimizes. Depending on the quality of the raw material, K+S needs to adjust various process values. Also, part of the process is cyclical. To control the process, the operators so far have been relying on their experience. The software does an even better job so that the quality criteria of the end product are always kept while producing at an economic optimum. Mr. Carsten Laukner is Program Manager in the department ‘Digital Transformation’ at K+S AG in Kassel, Germany. He states: “We have seen significant improvements in process stability and product quality in our potash plant in Unterbreizbach while using the process optimization technology of algorithmica. It was easily and quickly deployed and accepted by the operators as a useful advisor.”

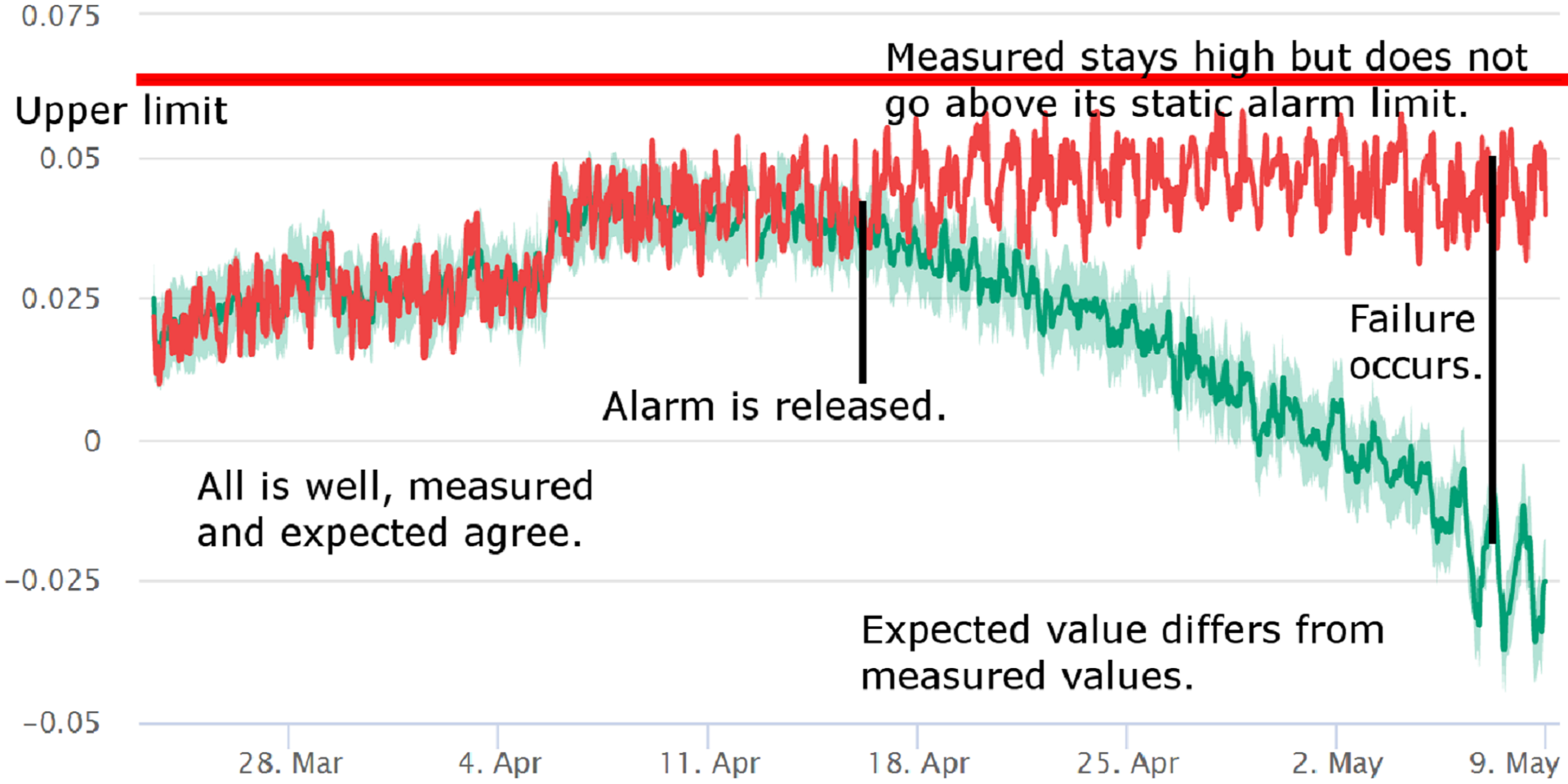

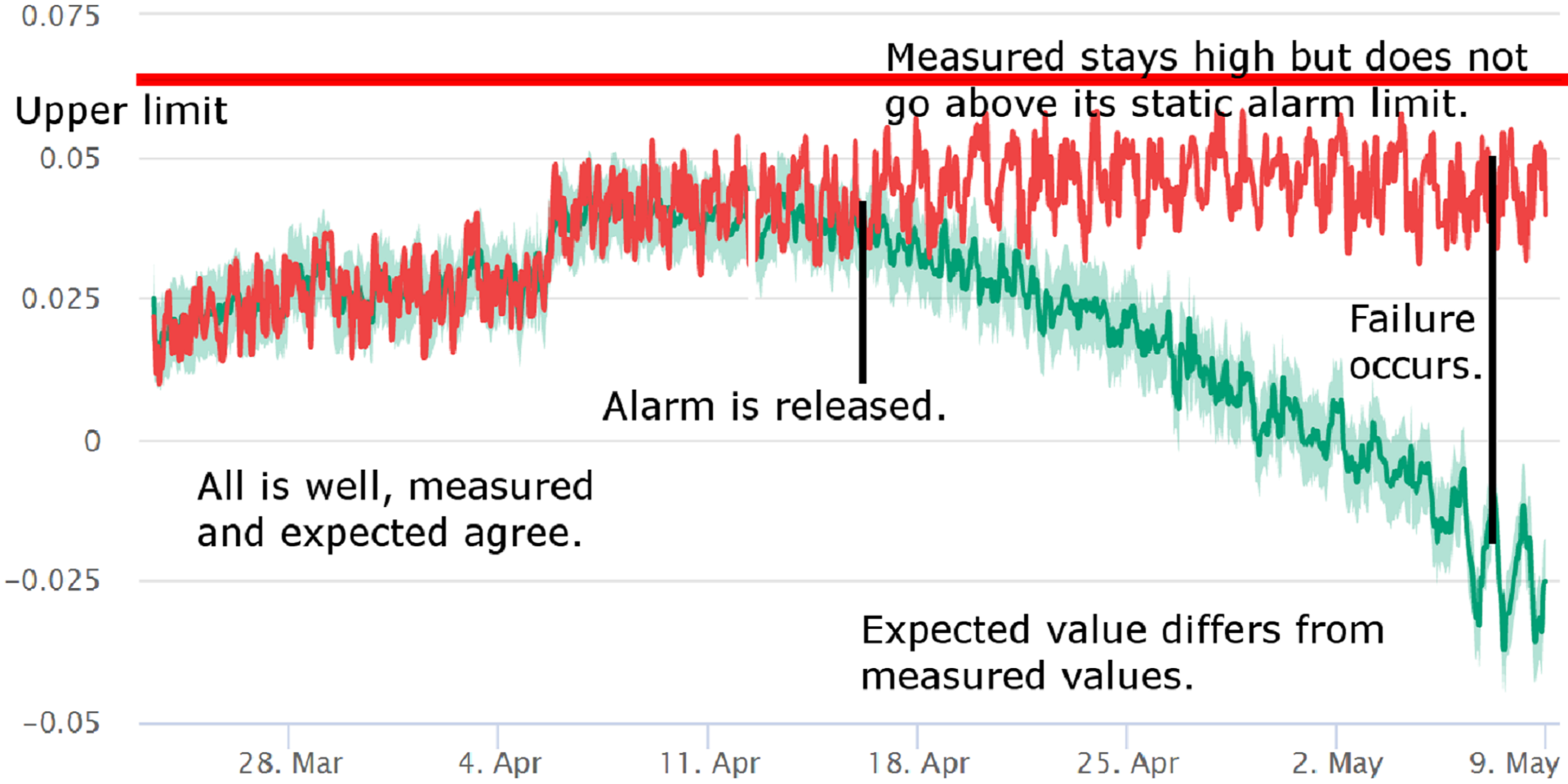

Condition monitoring looks at each measurement on its own and decides if it is too small or too large relative to a specified limit value. This is known to lead to many false alarms as well as states where the asset will fail but that remain unalarmed. Additionally, the effort to set the limiting values is time-consuming and bureaucratic.

Machine learning offers a holistic analysis that quickly and accurately reports on current machine health and makes a prediction to the extent of ‘next week Thursday, twelve o’clock you will have a failure’. By detecting a failure before it occurs, both the availability of the plant and its overall yearly production can be increased, while the maintenance budget can be lowered.

As many plants these days are being run over the originally designed capacity, maintenance is a real challenge. “I would say maintenance is the biggest challenge for aging plants,” Dr. Bangert states. “As the plant gets older and older, the equipment will fail more and more often. And then you run into the problem of having to repair it.” algorithmica’s tools can tell in advance whether some unhealthy condition or failure is about to take place. “For process plants, this means that they can get rid of preventative maintenance. They can also get rid of all the fire-fighting methods that need to be put in motion when they wait for a failure to actually occur. Most of all though – and this is the primary benefit to the customer,” Dr. Bangert stresses, “is you get rid of collateral damage. If you can repair an asset before it breaks, it costs you X. If you wait for it to break and then repair it, it will cost ten times X.”

This methodology has been verified in many process industry plants on a variety of rotating and non-rotating equipment such as gas, steam and wind turbines, compressors, pumps, heat exchangers, distillation columns and valves. It can easily and quickly be tried out in any plant as it just requires the installation of software and the building of models using historical data.

Machine learning models are also used to improve plant performance. “A process plant has set points where the human operator controls that plant and it is the operators’ job to change the set points in whatever way he believes is the best in order to react to the influences of the outside world,” says Dr. Bangert. “The outside world usually offers two major influences: one is the weather and the other the raw materials that go into the plant. These change in quality and composition, and also vary from supplier to supplier so the behavior of the plant must be modified to accommodate this. The human operator does this based on his experience, and he does a very good job, but not the optimal job.”.

What is also seen in a plant is that every eight hours the shift changes. “The plant operates 24 hours a day, seven days a week, so you might have up to maybe eight different groups of people that run your plant,” Dr. Bangert continues. “And every time the shift changes, settings are also changed, but a plant is large, so it takes quite a few hours for those changes to actually be realized into a stable situation. Eight hours later however the next shift comes and changes things again. So, the plant is consistently in a state of change, never functioning optimally. What you need is a consistent operational philosophy that you can run 24 hours a day and for this you need a computer program.”.

Mr. Puethe, Engineering Manager with Ashland, states: “Ashland uses the optimization suite APO in its formaldehyde production facility in Marl, Germany to maximize financial profitability and to prevent foaming. There is great potential for profit increase via changing the setpoints for various process elements.”

In addition to predictive maintenance and optimization, algorithmica offer a selection of other solutions. One of these is the ‘intelligent soft sensor’. Though this may sound like something tangible, it is – again – a formula. Dr. Bangert explains: “Sometimes in process industry plants it is difficult or very expensive to measure something. A primary example is gas chromatography that is quite expensive and very sensitive. They break quite often, especially in harsh conditions. In this case you might want to compute rather than measure. So, are you able to compute it based on the other variables that you can measure easily and cheaply? That’s where a soft sensor would come in.”

Dr. Bangert tells that especially in the last 1.5 to two years he has seen a real revolution taking place in the industry. “Virtually every company in chemistry, power generation, or oil & gas has started a new corporate department that is responsible for digitization, Industry 4.0, IoT, and so on. These departments oversee bringing new methods into the corporation.” These departments have two options: either develop methods on their own and deploy them in the corporation or buy tools from outside and then act as the consultants that implement the tools. “Most of them decide first to develop on their own, and then they figure out fairly quickly that this is very time-consuming and expensive,” says Dr. Bangert. “Whereas when you buy a tool from outside you can deploy it today, so you get a time benefit of perhaps three to four years and can stay focused on your core business. In addition, a software company has many customers and receives feedback from lots of them, so the software gets better and more mature at a much faster rate than when you develop in-house.” Of course, this is good news for algorithmica, as they would like to expand their business. “Apart from our home market in central Europe, we are focusing on the United States,” Dr. Bangert tells “where we have been active for about a year and a half. In Germany I would like to have reached the stage of corporate rollout soon.”

Artificial intelligence deals primarily with natural languages such as getting the computer to give you product advice while surfing a website. Dr. Bangert explains, “Machine learning however deals with numerical data. As an example: when you have 20.000 sensors installed in a refinery and you want to come up with a formula that governs the dynamics of that refinery, that’s machine-learning. Machine-learning deals with numbers, AI deals with words.” Machine learning is the key to all algorithmica’s solutions, which basically means the formula is developed automatically, without the involvement of a human expert. More information about machine learning is available in the book ‘Optimization for Industrial Problems’ that Dr. Bangert wrote (Springer Verlag) as well as on the website www.algorithmicatechnologies. Or contact Dr. Bangert directly with any question via p.bangert@algorithmica-technologies.com